Sustainable manufacturing through digital supply chains with Wagner Informatik & Siemens

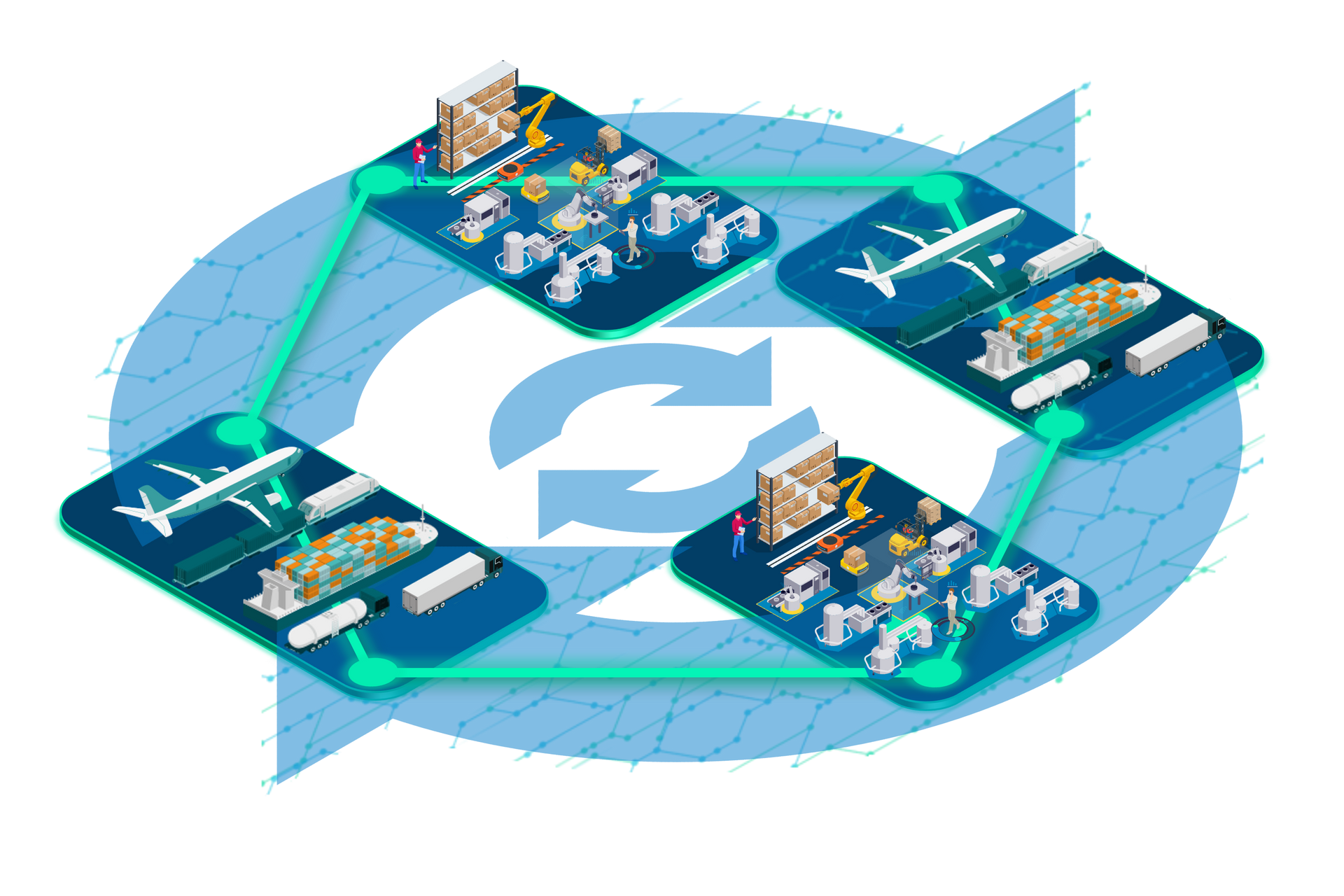

With Siemens AX4, your production supply chain becomes more transparent and resilient. The cloud-based platform enables a central overview and real-time control of all logistics processes, so that you can react flexibly to changes in the market and demand. AX4 supplies production planning with important real-time data, such as deviations, and thus improves planning reliability. This enables optimized production utilization and ensures that your resources are used efficiently. Close integration with your existing systems optimizes production and logistics processes, avoids bottlenecks and increases efficiency. Intelligent automation accelerates your processes, and a central database enables well-founded decisions in real time. The result is a significant reduction in production costs and an increased return, as fewer resources are wasted and production is more precisely tailored to actual demand. A strong, future-proof supply chain that sustainably improves your production is thus guaranteed.

Collaboration along your supply chain

Modular, Integrative and Efficient

Optimize collaboration and transparency in your supply chain through seamless integration of partners and systems. The AX4 Collaboration Suite, used by more than 500,000 users, connects digital processes with real logistics, creating an intelligent bridge between the virtual and physical worlds.

Modular cloud solution

Rely on AX4, a modular SaaS solution for your supply chain that grows flexibly with your requirements. Developed with a clear separation of data, logic and user interface, AX4 enables easy adaptation to individual requirements - for a solution that is scalable and ready for use at any time.

Integration

Thanks to AX4's powerful web service interface, the solution can be easily integrated into almost any existing system - regardless of the system landscape. This means you can integrate AX4 seamlessly into your IT infrastructure and, if necessary, adapt it as an individual white label solution.

What does AX4 offer for your production?

Optimize your production and supply chain with an integrated cloud platform. Simplify your production and logistics processes with a cloud-based platform that enables fast and smooth communication across all locations and departments. With the AX4-based Control Tower solutions, you can replace isolated island solutions with a central, fully integrated solution - perfect for manufacturing companies that want to bring transparency and efficiency to their supply chain.

Seamless integration and communication for maximum efficiency

Integrate AX4 effortlessly into your existing IT landscape to promote seamless collaboration across departments and company boundaries. Your entire supply chain – from production to warehouse to delivery to the customer – benefits from a seamless connection between systems and actors that enables real-time transparency.

Efficient

Document management and optimized logistics processes

Create and transmit all the necessary documents for inbound and outbound transport, from pickup orders and delivery notes to waybills and labels. Through rule-based validations and automation, you can accelerate your logistics processes, improve production planning and ensure that goods and raw materials arrive on time and cost-effectively.

Reliable planning and cost efficiency throughout the supply chain

Plan the next steps in production and warehousing with reliable real-time data and optimize your entire supply chain. The high-performance AX4 WebService interface makes it possible. Reduce production downtime, increase efficiency and ensure stable processes - from production to delivery to the customer.

The advantages at a glance

Efficiency - Automation - Transparency

Optimization of operative transport management

Modular cloud software: flexibility and efficiency combined

Modular software is a modern type of software architecture that aims to develop individual software components as independent modules. Each module is self-contained, can function independently of one another and perform specific tasks or functions. These modules can be individually combined, expanded or adapted without having to change the entire system. In the cloud, this means that companies can put together their software environment in a tailor-made and flexible way - precisely tailored to their current and future requirements.

Scalability

Modular cloud software makes it easy to add new features or capacities without having to restructure the entire system. This gives companies the flexibility to expand their applications and resources to respond to changing business needs

Adaptability

Every organization has specific needs that can change quickly. Modular cloud software allows the system to be flexibly adapted and new modules to be added or replaced as requirements change.

Cost efficiency

Since each module can be purchased and operated separately, companies only pay for the functions they actually need. This avoids high initial investments and reduces their operating costs in the long term.

Ease of maintenance

Errors or upgrades in one module can be carried out without affecting the operation of other modules. This leads to fewer system failures and ensures greater stability in everyday life.

Future-proof

The modular structure means that new technologies or updates can be easily integrated without having to redevelop the entire system. This helps to make the software future-proof and remain innovative in the long term.

All modules at a glance

- smart production and logistics

Order Management

Efficient order management for reliable production supply!

With the Order Management module, you can precisely control your procurement network and enable automated processing of release orders through to collection. The central management of all order processes - from supplier confirmation and the definition of shipping specifications to the creation of delivery notes and the management of collection orders - streamlines and accelerates the entire material flow to production.

The seamless integration of all parties involved, such as suppliers, freight forwarders, warehouses and production sites, allows real-time transfer of order data and offers full transparency in every process phase. End-to-end monitoring with milestone monitoring enables continuous control of the order status and ensures that all necessary transport documents such as labels and waybills are created automatically. This reduces delays and ensures that materials are always in the right place at the right time.

With this comprehensive overview of every order, you increase the efficiency, reliability and transparency in your procurement network. The optimized control of the ordering and collection processes ensures that production is supplied without interruption, thus ensuring stable and timely production planning.

Optimal order control

for

efficient production planning

Automated order processing

The automated processing of release orders through to collection increases efficiency and reduces manual errors. The central management of all orders optimizes the flow of materials to production, thereby minimizing delays and bottlenecks. The automatic creation of delivery notes and shipping instructions ensures a quick and error-free handover to the freight forwarders.

Real-time transparency and improved production planning

Real-time transfer of order data ensures complete transparency on the status of each order, so that production is always informed. End-to-end monitoring with milestone monitoring enables precise planning and timely delivery of materials, which supports on-schedule production. Central control of all pick-up orders ensures seamless transfer of materials to the production lines, without unnecessary delays.

Cost and process optimization

By detecting deviations in the ordering process at an early stage, bottlenecks are identified in good time and can be resolved quickly. A clear overview of all orders helps to make tenders efficient and optimize the costs of logistics services. The automatic creation and verification of transport documents such as labels and waybills reduces administrative effort and saves time.

Transportation Management

Efficient control of your transport processes!

Optimize your transport operations with a holistic solution that gives you complete visibility and control over your supply chain.

By centrally merging data from different sources, transport orders can be processed automatically and sent to the relevant service providers. This reduces manual errors and speeds up the entire process.

Track shipments in real time and get detailed information about the current location and accurate forecasts of the expected delivery time. Automated notifications inform everyone involved of deviations or problems so that they can react quickly.

Through this comprehensive control of the entire transport process, you not only improve efficiency, but also reduce transport costs and optimize the entire supply chain.

Transportation Management Inbound

The Transportation Management Inbound module enables transport orders from various data sources and formats to be efficiently processed, validated and assigned to the correct units. By bundling shipments, assigning tracking information and automatically creating the necessary accompanying documents, the module ensures smooth supply.

Milestone plans enable precise control and monitoring of multimodal transports.

Real-time position data and precise

ETA forecasts

can optionally be integrated via

partner platforms

in the Siemens Digital Logistics network. This means that follow-up processes can be triggered automatically when important

milestones

are

reached

or

missed.

To efficiently manage delivery at the site, time slot data is linked to shipment and manifest information, automatically determining specific delivery times and loading gates. This prevents overloading at the dock and ensures that necessary personnel and equipment are available on time.

The inbound module not only improves transparency along the entire supply chain, but also increases production capacity utilization because supply is optimally guaranteed and unnecessary transport is minimized. Production planning is enriched and optimized with real-time data.

Production optimization starts with strong inbound logistics

Optimized material availability and planning security

With greater consolidation potential thanks to detailed transport forecasts and targeted allocation to freight forwarders, AX4 ensures that materials are optimally bundled and arrive at the production site at the right time. This transparency helps production planning to use resources efficiently and avoid downtimes due to missing materials.

Complete transparency and proactive deviation control

AX4 provides complete transparency across the entire shipping process, including tracking down to material number level and estimated arrival times. Deviations from the milestone-based rule process are escalated early so that delays can be quickly identified and action taken - for smooth and continuous production.

Flexibility and Efficiency in Logistics Management

With support for flexible logistics strategies, such as early receipt of goods by suppliers, AX4 ensures that critical components are available on time. Self-invoicing also simplifies the billing process, reduces administrative effort and ensures seamless integration into production processes.

Transportation Management Outbound

With the Transportation Management Outbound module, all transport-relevant data can be centrally consolidated and made available via a uniform interface. This gives production, logistics and shipping departments direct and structured access to real-time information, which replaces manual, error-prone processes and significantly increases process reliability.

Transport orders

from production logistics are

automatically

accepted, sent to the respective freight forwarders and

independently

supplemented by the system with the necessary

shipping

and

transport documents.

The seamless recording and transmission of

tracking data

takes place

across systems

via

API,

web access or

mobile applications and provides real-time status information to all those involved, from

distribution centers

to the

end customer. Advanced search functions for reference and order data ensure seamless

transparency

and

traceability

of the

supply chain. Routine tasks and standardized workflows can be fully automated so that time- or event-based notifications in the event of deviations enable

proactive control

and

timely escalation.

The outbound module therefore ensures high process stability and on-time delivery of finished products, which enables continuous optimization of the supply chain and a sustainable increase in customer satisfaction. The improved reliability and transparency in the shipping process are essential factors in meeting delivery commitments and production targets and strengthening long-term customer relationships.

Production and delivery performance through precise outbound logistics

Automated and efficient logistics processes

The outbound module enables the automatic transmission of shipment data to connected freight forwarders, whereby shipping orders from production are seamlessly transferred to transport logistics. Freight forwarders have flexible options for reporting tracking data to ensure transparent and timely communication along the entire supply chain.

Comprehensive transparency and event management

A central, cross-location tracking dashboard provides complete transparency of all ongoing shipments and their status. The easy findability and proactive escalation of deviations in the milestone-based standard process enable fast response times and support continuous production planning without interruptions.

Detailed analyses and cost efficiency

The system simplifies the analysis of shipping volumes and supports tenders for logistics services. Incoming freight invoices are verified based on the actual completed shipments, meaning only correct costs are posted. Automatic crediting for service providers and internal cost center allocation reduce administrative effort and increase cost efficiency.

Appointment und Dock Management

Efficient time slot and dock management for smooth loading and unloading processes!

With the Appointment and Dock Management module, you can efficiently manage incoming deliveries and optimize the loading and unloading processes directly in your production environment. Reserve, book or cancel time slots for trucks and deliveries quickly and easily - and link them directly to the respective production orders.

Flexible time window options and predefined templates enable targeted control and equalization of traffic flow in order to avoid production interruptions due to delayed or poorly coordinated deliveries.

Vehicle type, driver data and specific requirements such as the need for a crane or the handling of hazardous goods can be easily added. This ensures a complete overview and helps to identify the need for special resources at an early stage.

Before booking, the system checks the plausibility and validates all required freight documents. This ensures that all relevant documents such as delivery notes and certificates are verified in advance, which ensures both efficiency and legal compliance.

The module saves valuable time and reduces the effort for senders, drivers and recipients alike. By creating clear processes and linking dock planning with production logistics, it ensures a smooth, timely and resource-saving supply of materials in production.

Optimized scheduling and dock planning for efficient production logistics

Efficient resource planning and delivery control

The module enables precise planning of deliveries, which means that resources in production are used optimally. Flexible time windows and the recording of vehicle and driver data ensure better coordination and reduce delays. Special requirements such as cranes or hazardous goods can be taken into account at an early stage. This leads to better predictability and reduces delays in the production process.

Validation and linking with production processes

The system checks the plausibility and validates freight documents before booking, thereby reducing sources of error. By linking deliveries with production orders, the material flow is optimally tailored to production needs, which increases efficiency.

Freight Cost Management

Cost control in logistics - maximize efficiency in your production!

The Freight Cost Management module offers an automated and customizable solution for the precise calculation and distribution of freight costs in logistics. This module gives you clear insights into transport costs, which can be calculated individually depending on factors such as volume, transport mode or distance. This allows freight costs to be allocated precisely to the respective production orders, cost centers or customers, which enables transparent and efficient cost control.

Invoices and credit notes are created automatically based on relevant data such as shipping volume, distance and other additional services. The module compares expected and actual invoice amounts and automatically marks deviations for review. This optimizes the comparison between calculation and actual costs and reduces manual checks.

Freight costs are generated based on existing contracts and can be used for tenders or offers to secure the best conditions. The audit and approval processes can be individually adapted to ensure efficient and error-free processing.

In addition, the system supports the automated allocation of freight costs for internal and external financial accounting, so that complex tariff structures can be easily mapped and integrated into the overall accounting. This saves both time and resources and ensures complete and error-free cost control.

Optimized freight cost control for cost-efficient production

Precise allocation and complete transparency of freight costs

The Freight Cost Management module provides an automated and customizable solution for calculating and distributing freight costs based on factors such as volume, distance or transport mode. This enables precise allocation of freight costs to the correct production orders or cost centers, increasing transparency in production calculation.

Automation of invoice processing and clarification

Freight costs are automatically calculated based on shipping volume and other factors such as transport mode or additional services. Expected and actual invoice amounts are compared and deviations are marked for review. This reduces manual effort and ensures more precise billing in production.

Efficient account assignment and easy integration into financial accounting

The complete automation of the accounting for internal and external freight costs means that even complex tariff structures can be efficiently mapped in the system. The seamless integration of freight costs into financial accounting simplifies billing and reduces administrative effort in production and beyond.

Extended Workbench Management

Efficient integration of external partners for your production!

The concept of the “extended workbench” makes it possible to optimize production and logistics processes by outsourcing to external partners.

To manage these processes smoothly, precise integration of inbound and outbound processes is required.

Modern transport management solutions, such as AX4, offer enormous advantages here by bundling all relevant data and documents centrally and offering complete transparency and comprehensive control options.

By seamlessly integrating external partners into your production, you achieve more flexible, faster and more cost-efficient manufacturing. Real-time data and automated workflows ensure precise control and enable you to react immediately to changes in production or logistics.

This end-to-end networking not only optimizes the efficiency of your production, but also improves the entire value chain by avoiding bottlenecks and accelerating production throughput.

With an integrated system of inbound and outbound management, you can effectively manage your external partners and significantly improve collaboration along the entire supply chain. This way, your production remains stable and efficient even in dynamic markets.

Benefits of Extended Workbench Management for efficient production and logistics

Optimized process integration

Through the seamless integration of inbound and outbound processes, companies gain complete transparency in their processes. External partners are efficiently integrated into the production chain so that all relevant data and documents are managed centrally and updated in real time. This precise control of external collaboration reduces delays and enables a rapid response to changes in the supply chain.

Flexibility and increased efficiency

The "extended workbench" enables a more flexible design of production processes. By outsourcing certain steps to specialized partners, companies can better adapt their production capacities and avoid bottlenecks. Automated workflows and real-time data integration optimize production efficiency and ensure a faster response to changes in demand or production bottlenecks.

Cost reduction

Outsourcing production processes leads to a significant reduction in your own operating costs. By selecting and managing external partners, capacities are used efficiently, allowing companies to reduce their resource costs and optimize production costs at the same time. Automated processes and central control also reduce administrative costs and improve cost control.

We advise the following industries, among others

The key to the success of an implementation or expansion project lies in the holistic view of the end-to-end processes in the company and their

consistent implementation. Harmonization and standardization aspects play a key role here, in addition to the practical experience of the consultants.

Every company has its own individual characteristics and therefore individual requirements for standard logistics or business management software, such as the SDL Collaboration Suite AX4.

We would like to show you the clear advantages of optimized logistics and its positive impact on your production, based on the successes of our customers!

Value creation in transition - your intelligent supply chain!

Whether it is about managing relevant information for a more efficient value creation process, connecting procurement and production processes to your supply chain or transparently controlling your financial flow, we have a solution!

We share the vision of our strong product partners and see active, digital supply chain management as a key factor for the success of your company!

With our expertise, we support your logistics projects with the following services:

- Definition and documentation of processes in logistics projects on the basis of UML

- Design and implementation of AX4

- Optimization of existing AX4 solutions

- Creating specifications / detailed specifications in the area of logistics

- AX4 trainings

- Test management

- Deployment of AX4 (Hot Deploys, Service Packs, etc.)

- International rollouts

- GoLive-, Post-GoLive- and Hypercare-Support

- Logistics Manufacturing (TMS, WMS, PPS)