Opcenter™ Quality

The quality of products and processes over the entire product life cycle is a prerequisite for achieving corporate goals.

Quality largely determines the competitiveness of all manufacturers, and high-quality standards require the integration of quality processes in all manufacturing companies.

We at Wagner Informatik support you with the software Opcenter Quality from the product idea to implementation and use.

Major Points Opcenter Quality

- Advanced product quality planning (APQP)

Planning and project management of quality activities with milestones

Global visualization of project status

Integrated change management in APQP supported by integrated workflows - Failure Mode and Efects Analysis (FEMA)

Standard-based risk analysis for product and process design

Several Industry Standards supported (AIAG/VDA, AIAG, VDA, AS)

Methods, tools and best practices to produce robust, accurate and complete D-FMEA / P-FMEA - Inspection Plan Management (IPM)

Central Inspection Plan Management -Creation of inspection plans for FSI, Receiving Inspections, SPC and outgoing goods control.

Automatic and fully-integrated change management

Characteristic definition for variable, attributive and visual characteristics: Gage allocation, inspection rules, control charts - Gage Management

Administration of all calibration data, including normal values and information on measurement inaccuracy

Gage management for occupational health, safety and environmental protection - Order Management (OM)

Processing of all inspection-relevant information

Rationalized/unified inspection strategies and operating procedures - First Sample Inspection (FSI)

Efficient creation of FSI reports for both supplier and customer samples

Support to dimension, function, material, capability and reliability inspections

Manage APQP / PPAP - Incoming Goods Control / Outgoing Goods Control (IGC/OGC)

Integrated workflows to report disposition decision to ERP or Inventory Management systems and automatic creation of complaints

Supplier agreements (just-in-time/just-in-sequence/ship-to-stock) for reduction of inspection costs - Statistical Process Control (SPC)

Operator-friendly due to individual configuration options

Optimization of inspection cycles for the reduction of inspection and defect costs

Available SPC Web –HTML5 Interface - Quality Main Control

Quality Main Control module provides with cross departmental visualization of quality problems

and an overview for the head of production, foreman, shift leader and quality manager - Evaluation EVA / EVA-X

Allows performing evaluation of collected data supported by standard graphs and diagrams - Inspection Reports

Inspectioncertificates can be generated based on the results of IGC, SPC, OGC and FSI inspection orders - Supplier Assessment

Hard facts for the supplier assessment: QNC (delivery quality), date reliability, quantity reliability

Failure Mode and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) is a methodology that enables companies to assess risks in connection with possible procedural and process errors. The damage caused by potential defects can often be linked to increased warranty costs, impaired product functionality and safety, and the inability to meet required industry standards, among other possible consequences.

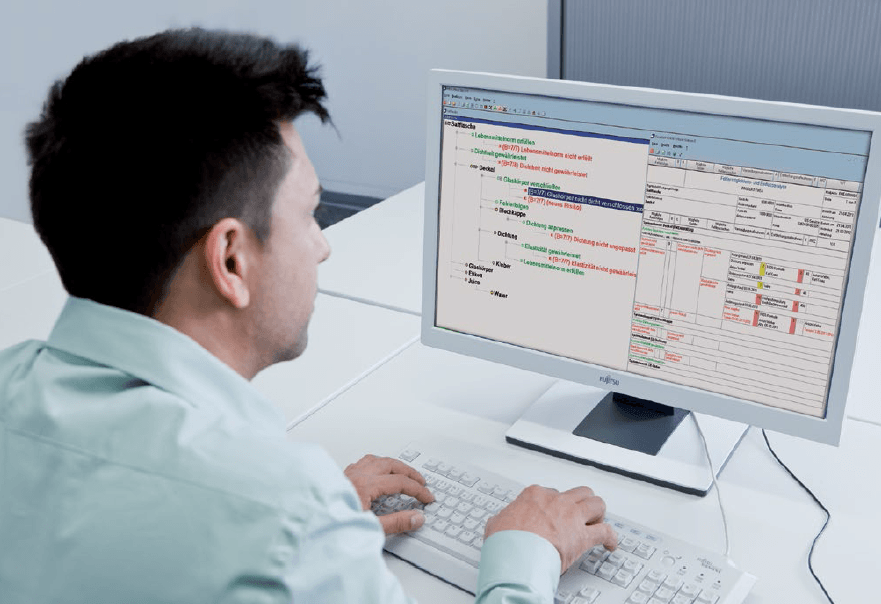

The Failure Modes and Effects Analysis (FMEA) module from Opcenter Quality supports you in preventive failure avoidance by allowing you to evaluate the effects of potential failures and risks at an early stage in the planning phase. With this solution, you can create an intuitive FMEA analysis and take appropriate measures to efficiently manage potential errors in real time.

With Opcenter Quality FMEA you can easily handle complex designs and processes in a tree-structure, supported by network diagrams, for sorting data on all hierarchies and levels.

Cross-industry QMS solution

With the integrated process functions (quality control cards, statistics, quality gates) production errors can be detected and further processing and dispatch of non-compliant materials can be prevented.

MOM

Advantages with Opcenter Quality

- Efficiently manage the cause and effect analysis in real time

- Increase the functional safety and reliability of your product

- Shorten product develeopment processes

- Adhere to industry-standard quality standards and project deadlines

- Reduce warranty claims and related costs