Current challenges for manufacturing companies

In a global manufacturing environment, manufacturers are looking for ways to reduce time to market, control costs, and manage complexity while delivering high quality. During the planning and execution phases, factors such as connectivity to manufacturing engineering and production, effective change management, alignment of assembly lines, and forecasting of production orders must be considered.

PLM-manufacturing solutions help you manage product and process knowledge in a single environment. Easy Plan offers various collaboration and analysis tools that help you perform manufacturing planning digitally, thereby avoiding production downtime due to design errors.

Production planning with a task-oriented and easy-to-use web solution

The Easy Plan web solution is built on the industry-leading Teamcenter® software for product lifecycle management (PLM), enabling you to leverage existing product and process information while facilitating cross-departmental workflow sharing. This helps optimize your bills of materials and work plans, gather feedback from production, and effectively implement production-related changes.

Early production planning in PLM

Many customers primarily use Teamcenter as a PLM solution for engineering-driven processes. The transition to the logistics-focused ERP system usually begins early, with the engineering bill of materials (EBOM), or, at the latest, with the manufacturing BOM (MBOM) for production and plant operations. To generate a production order, only basic operations are defined, which complete the work plan in the ERP with minimal information. Technical details are often still maintained in separate Excel sheets. But why double the effort and add unnecessary complexity?

We want to highlight the clear advantages of early production planning within PLM and demonstrate how our customers are already succeeding. Beyond the initial creation of a work plan, early tasks such as work instruction creation and production balancing forecasts play a crucial role in generating added value. This is our area of expertise, and we will showcase our core competence in manufacturing.

The core content for PLM Manufacturing with Easy Plan consists of

- Digitize work instructions for workers

- Generating and adapting production-related MBOM from the EBOM

- Efficient and fast creation of a work plans (templates, standard texts)

- Accountability checks for MBOM and BOP

- Document storage for processes amd operations

- Preparation for transferring bills of material and work plans to ERP and MES

- Configuration of variants and scope

- Line balancing and operating time analysis

- Estimation of cycle time and production rate

- Problem reporting and guided change management

- Enables an intuitive user experience and ease of use for process planning

- Standardization and reuse of best practices

- Development of bill of processes that reflect shop floor scenarios

- Utilize robust configuration and change management for manufacturing data

- Optimize

cycle times and

production rates

Assembly planning with Easy Plan

Easy Plan provides a unified environment to capture all manufacturing data from different systems, helping you manage global production scenarios. It is seamlessly connected end-to-end with both design and manufacturing execution, allowing data and changes to flow effortlessly between them. This streamlined integration reduces the cost and time of new product introductions (NPI), enables direct feedback from manufacturing, and supports continuous improvements in processes and quality.

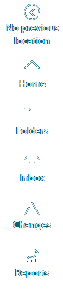

Closed-Loop Manufacturing

- Connect product design, manufacturing engineering, and production with a robust digital thread

- Control processes through effective change management

- Use Easy Plan as the "single source of truth" and central planning platform

Central assembly planning with Easy Plan

Easy Plan provides a task-based solution to define and manage the manufacturing bill of materials (MBOM) and reconcile product changes to the engineering bill of materials (EBOM). Managing EBOM and MBOM in the same place increases accuracy and reduces inventory costs as changes can be implemented easily and without delays. Virtual validations can be performed to ensure the accuracy of the EBOM.

Many manufacturing variants - one solution

Easy Plan for ETO

(Engineer to Order)

- Recommended for planning products with low quantities and low variability, typically characterized by longer cycle times, where planning is primarily influenced by the product structure.

- This solution utilizes a classic BOP data model.

- Industries commonly benefiting from this solution include Aerospace & Defense (A&D) and shipbuilding.

- In some sectors, both ETO and BTO/BTS/CTO solutions may be applicable. However, the choice depends on the customer’s specific business processes. Customers can also implement both solutions within their environment, using different approaches for various products as needed.

Easy Plan for BTO\BTS\CTO

(Built to Order \ Built to Stock \ Configure to Order)

- These approaches are recommended for planning mass production with high volumes and high variability, where planning is primarily influenced by the plant layout, and line balancing is necessary to eliminate bottlenecks in the assembly line.

- The planning utilizes the Plant-BOP data model.

- Typical industries for this solution include the automotive industry, automotive suppliers, and household appliances.